We hope to be the best supplier of marine cone rubber fender in China.

Description of Marine Cone Rubber Fender:

The marine cone fender is the result of continuous product development. This fender design is based on the cell fender which was introduced to worldwide markets more than 25 years ago. This type of fender can be considered as the latest in state-of-the-art molded fender products. They provide an excellent energy capability with a low reaction (their designed compress deformation rise from 52.5% to 70% while the reaction force is unchanged).

Cone rubber fender has the highest energy absorption and lowest reaction force of any fender types. The high efficiency makes it has excellent performance and fewer costs. All cone fenders are single piece moldings so they are robust, long life span and easy install. In most projects, the frontal frame is generally used in conjunction with the cone type fender system. Generally, the frontal frame is including steel panel and UHMW-PE face pad.

Some of the most prevalent application for cone type fenders are at off-shore open berths, container terminals, oil wharf, and other large docks as it resists high shear forces and can handle large panel weights and have the highest energy to reaction ratios. They work just as well mounted in reverse(with its smaller face against the quay wall) so designers can make use of this type fender on narrow harbor structures where the footprint area is limited.

Accessories of Marine Cone Rubber Fender system:

Cone rubber fender

Chains and accessories(U-anchors, brackets & shackles)

Steel panel painted with corrosion protection paints

UHMW-PE face pad

Fender fixing anchors & bolts

Features of Marine Cone Rubber Fender:

Very high energy absorption per fender weight.

Excellent under large berthing angles and shear.

Large range of sizes(300-2000mm)

Choice of standard & intermediate compounds.

Stable geometry maintains performance under all loading combinations.

Well proven design.

Easy and fast to install.

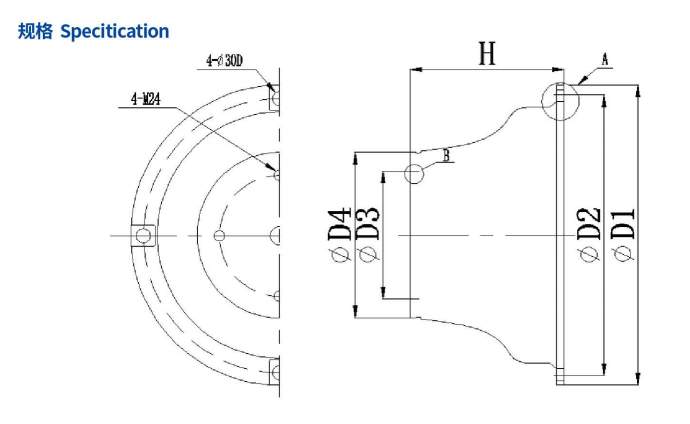

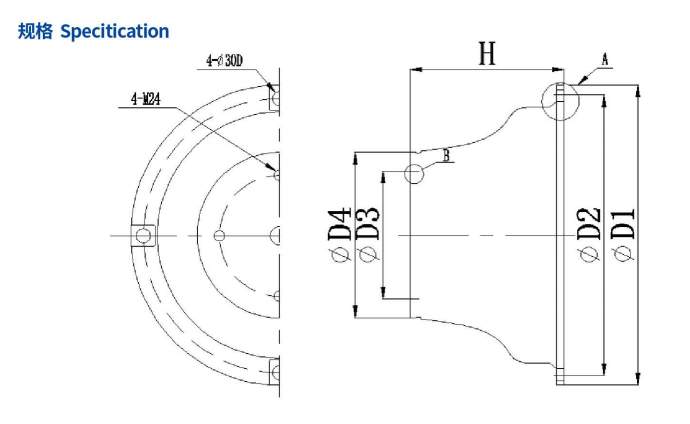

| 型号 Type | H(mm) | D1(mm) | D2(mm) | D3(mm) | D4(mm) | 孔数Holes |

| C500H | 500 | 750 | 675 | 325 | 425 | 4 |

| C600H | 600 | 900 | 810 | 390 | 510 | 6 |

| C700H | 700 | 1050 | 945 | 455 | 595 | 6 |

| C800H | 800 | 1200 | 1080 | 520 | 680 | 6 |

| C900H | 900 | 1350 | 1215 | 585 | 765 | 6 |

| C1000H | 1000 | 1500 | 1350 | 650 | 850 | 6 |

| C1100H | 1100 | 1650 | 1485 | 715 | 935 | 6 |

| C1150H | 1150 | 1725 | 1550 | 750 | 998 | 6 |

| C1200H | 1200 | 1800 | 1620 | 780 | 1020 | 8 |

| C1300H | 1300 | 1950 | 1755 | 845 | 1105 | 8 |

| C1400H | 1400 | 2100 | 1890 | 930 | 1190 | 8 |

| C1500H | 1500 | 2400 | 2160 | 1060 | 1360 | 8 |

| C1600H | 1600 | 2700 | 2430 | 1190 | 1530 | 8 |

EN

EN

AR

AR FR

FR DE

DE IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES